GO-15-HF™ and Metal Wear – The TECH for TECHIES

"A change in the chemical composition of the surface in the wear scar. The compositional changes extend to a depth of at least 200 Angstroms" (a linear measurement unit based upon atomic dimensions).

"A change in the chemical composition of the surface in the wear scar. The compositional changes extend to a depth of at least 200 Angstroms" (a linear measurement unit based upon atomic dimensions).

GO-15-HF™ is not a lubricant, it is a Metal Lubricity Technology® Product, "MLT".

It is an energy technology that through the interaction of its trade secret ingredient MBS4 combines with heat and friction to produce a thermal reaction resulting in molecules of MBS4 to combine with molecules of the metal surface.

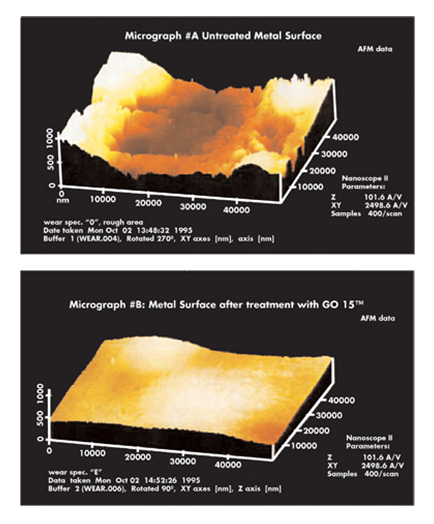

Micrograph Figure A (right, top) shows an actual microphotograph of the surface of the test bearing which was only treated with baseline premium oil.

The peaks and valleys in the metal surface are normal in an untreated metal surface such as a bearing or metal part in an internal combustion engine, but cause a significant amount of friction when placed in contact with another similar boundary surface.

Figure B - The microphotograph (right bottom) shows the results after the same bearing was treated with 6% per volume of GO-15-HF™. It was the conclusion of a nationally recognized, independent research and development laboratory that the presence of GO-15-HF™ resulted in; In summary, this nationally recognized, independent research and development laboratory indicate that the GO-15-HF™ treatment produced a much smoother wear surface with an altered chemical composition.

Another secret ingredient in GO-15-HF™ addresses the problem of "dry starts" which takes place in most automobile engines. Unlike large diesel trucks, automobile engines do not have a recirculating oil pump. This ingredient grips and clings to the metal boundary surface far better than oil and other oil additives. The ingredient changes the thixotropic index of base oils and actually elongates the flow characteristics of metal thereby increasing the oils lubrication effectiveness, and is not effected by the heat or viscosity of the base oil.

The third benefit of GO-15-HF™ starts immediately after the product is introduced to the component. It cleans the metal and assists in removing contaminant's that cause increased friction and contribute to higher emissions as automobiles age. These technologies work in conjunction with the changing of the metal boundary surface, and contaminates are encapsulated and carried to the oil filter for ultimate disposal. Unlike competitive anti-wear products, GO-15-HF™ does not leave a coating or any foreign deposits of any kind on any component part that could reduce the performance levels of the engine.

GO-15-HF™ is safe to use on any metal-to-metal friction boundary application and is compatible with all types and forms of lubrication oils, gear oils, compressor oils, hydraulic and differential fluids, manual transmission fluids, metal working fluids and greases. GO 15™ contains no fluorocarbons, lead, sulfur, silicon, Teflon®, or Molybdenum.

Once the action of MBS4 takes place within the engine, it does not remain in the primary lubricant carrier like other additives. Rather, since GO-15-HF™ is a metal technology product, it becomes incorporated into the molecular structure of the engine surfaces, i.e., cylinders, pistons, bearings, etc. This process takes place over time, and is facilitated by the heat and pressure generated by the engine.

GO-15-HFoz Bottle

GO-15-HFoz Bottle